Why The Wrap Shop invested in Summa F Series cutter technology from printMAX

To join its portfolio of carefully selected technology, including three Roland roll-to-roll printers - two Versacamms and one SolJet Pro 4 XR-640 - Essex-based cross-media print & graphics production company The Wrap Shop, recently invested in a flatbed Summa F series cutter from printMAX. For co-founder Steve Hart it was a simple decision - he had seen the machine in action.

Steve explained: "Ever since I saw what the Summa F Series could do at the Sign & Digital Show I've wanted one. Logically we didn't need a flatbed cutter, but when I saw how the machine could work with an 8 x 4 ft sheet of material I knew it had great potential. The model we sourced from printMAX can even handle 10 x 5 ft sheets of Foamex and Dibond, and 50m rolls of vinyl. And we could afford it.

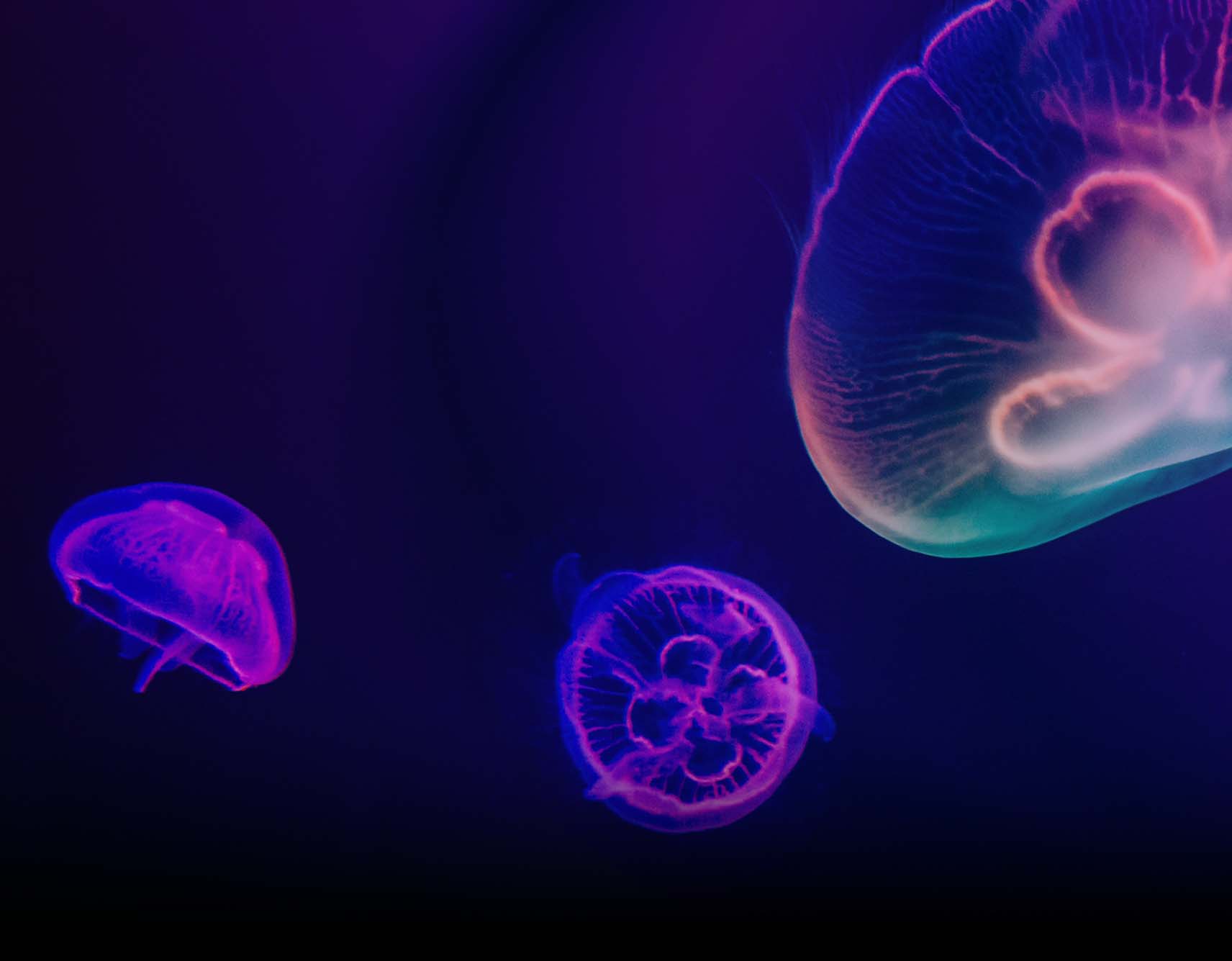

The F Series in action with Steve at The Wrap Shop. Photographs courtesy of Charlotte Crampton.

"The Wrap Shop specialises in all aspects of vehicle graphics and wrapping. We also design, produce, and install architectural graphics for the office and home, including windows, walls and floors. However, to date we have been producing a lot of customised vehicle chevron kits - they are very popular - and thanks to that chevron work we could afford to invest in the new Summa cutter."

Steve continued: "Ever since we started we have maintained our business vision of exceeding customer expectation, backed by practical investment in the best technology. We ask what our customer really wants to do and discuss how we can best supply it. We like to go that little bit further - is there a way we can do the job cheaper and with more impact?

"By bringing the Summa cutter into the workshop we have increased productivity, streamlined workflow and improved quality control. Because the production process is now all in-house, we can finish the work better and faster, which means we can meet increasingly hectic deadlines."

"The bottom line is, we depend on word-of-mouth recommendations from satisfied clients to keep the workflow constant; and to keep clients happy we invest in the best tools for the job, tools that allow us to bring our imagination and experience to bear on every project. People expect nothing less than our best, and providing it is at the heart of the team's job satisfaction."

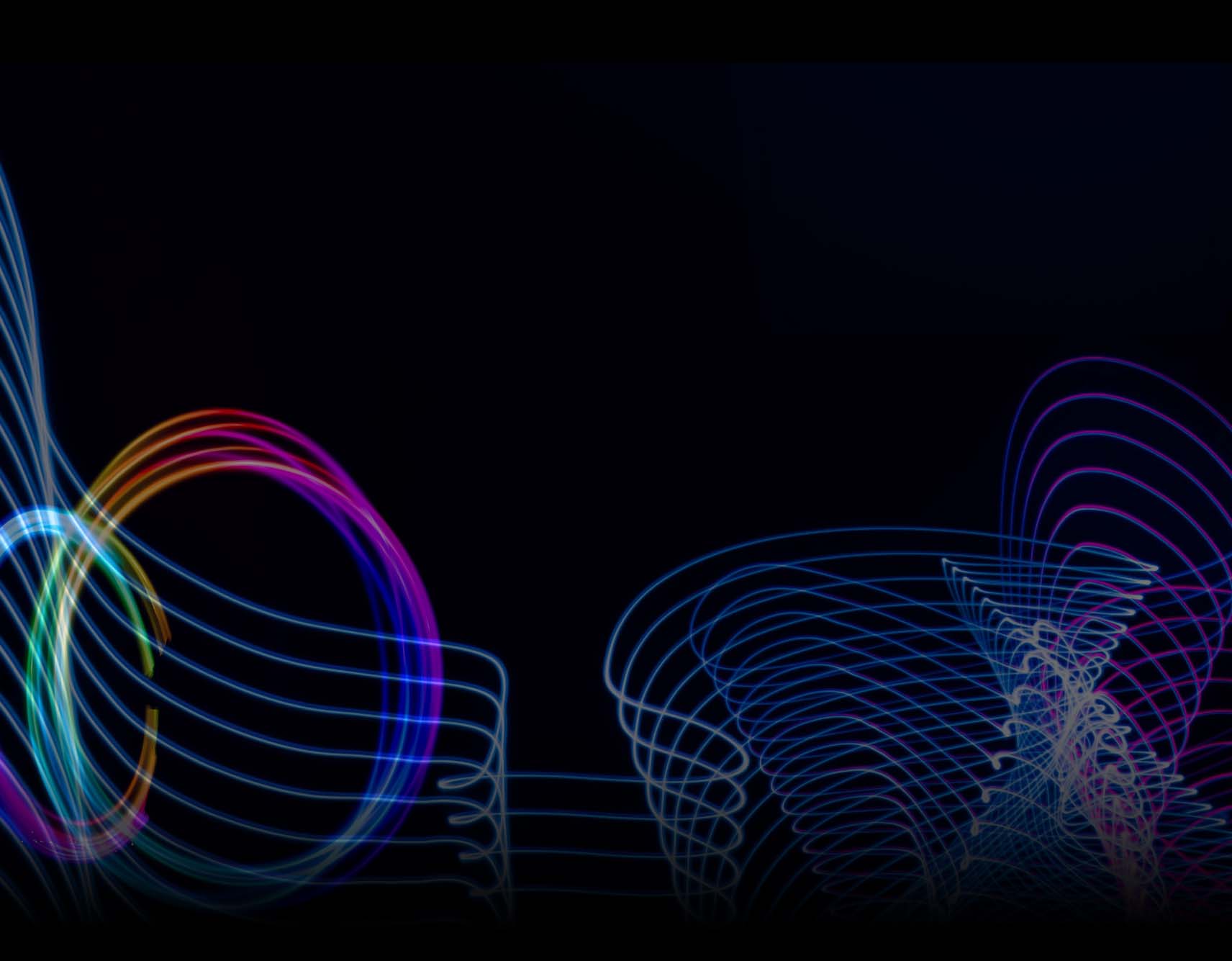

Finished products cut by the Summa F Series

The Wrap Shop "A product of its own success"

Summa cutters recently joined a printMAX portfolio that includes Roland, Mimaki and HP machines. Chris Martin, printMAX Head of Sales, explained how his company's expertise has served The Wrap Shop: "We have been long-term suppliers for The Wrap Shop, working with Steve from his first Roland VP300 back in 2008, to his latest acquisition, his Summa F Series cutter.

"The Wrap Shop is a product of its own success. As the scale of its graphics projects has grown and the demands on its machines increased, the company has invested in the best technology to meet that growth. As a specialist reseller printMAX has always been there to help ensure Steve gets the best return on his investment.

Steve in action using the Summa to cut vehicle graphics, increasing productivity.

"The Wrap Shop is an interesting case, if not unique. It uses roll fed printers and most Summa F Series cutters go to sites using flatbeds. However, Steve had seen the cutter in action. He could visualise its potential as part of his existing workflow and see how it might improve his productivity - which has proved to be the case."

Chris added: "Because The Wrap Shop is a long-term customer, printMAX has developed an in-depth understanding of its needs. This helped us ease its step towards purchasing the Summa F Series. The machine clearly met and exceeded the requirements of the company, opening a new realm of cutting and routing to its workflow, while also bringing quality control in-house.

"Central to its success is The Wrap Shop team's creative skills. A lot of Summa F Series customers will only cut very basic and generic shapes, such as squares, but these guys really go to town on their designs. It's always exciting to discover what they plan to do next; they can inspire the most jaded imagination."

Summa F Series

Managing Director Michael Bolton enthused: "With its core ethos of exceeding expectation, printMAX prides itself on transparency with its customers, and a part of this is our one-on-one business demonstrations in our Demo Centre. In its central South location, the Demo Centre has a huge range of machines, of which the Summa F1612 cutter has become a central feature.

"We offer customers an opportunity to book for live demos because we know that seeing and trying these machines first-hand provides an opportunity to experience this advanced technology and discover the incredible results they can achieve."

Steve Hart concluded: "I've known and worked with printMAX a long time; and when I told Chris Martin I was looking at investing in a Summa F Series - and he told me they were on the printMAX stock list - the whole thing became very straightforward.

"I trust printMAX to look after my technical requirements; they always have in the past and I will always use them in future. My customers know I will go that little bit further to meet their needs, I feel I get the same service from printMAX."

Steve, his dog (Lemmy) and his Summa F Series.

For more information about The Wrap Shop visit http://thewrapshop.london/

For more information on the printMAX demo room or to book a demonstration with one of their technical consultants, email info@printmax.co.uk or call 01420 511539

To keep up to date with printMAX news, offers and case studies follow @printMAXuk on social networks.