Steve Hart, The Wrap Shop

Why The Wrap Shop invested in Summa F Series cutter technology from printMAX

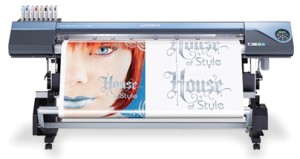

To join its portfolio of carefully selected technology, including three Roland roll-to-roll printers - two Versacamms and one SolJet Pro 4 XR-640 - Essex-based cross-media print & graphics production company The Wrap Shop, recently invested in a flatbed Summa F series cutter from printMAX. For co-founder Steve Hart it was a simple decision - he had seen the machine in action.

Steve explained: "Ever since I saw what the Summa F Series could do at the Sign & Digital Show I've wanted one. Logically we didn't need a flatbed cutter, but when I saw how the machine could work with an 8 x 4 ft sheet of material I knew it had great potential. The model we sourced from printMAX can even handle 10 x 5 ft sheets of Foamex and Dibond, and 50m rolls of vinyl. And we could afford it.The Wrap Shop specialises in all aspects of vehicle graphics and wrapping. We also design, produce, and install architectural graphics for the office and home, including windows, walls and floors. However, to date we have been producing a lot of customised vehicle chevron kits - they are very popular - and thanks to that chevron work we could afford to invest in the new Summa cutter."

Steve continued: "Ever since we started we have maintained our business vision of exceeding customer expectation, backed by practical investment in the best technology. We ask what our customer really wants to do and discuss how we can best supply it. We like to go that little bit further - is there a way we can do the job cheaper and with more impact? By bringing the Summa cutter into the workshop we have increased productivity, streamlined workflow and improved quality control. Because the production process is now all in-house, we can finish the work better and faster, which means we can meet increasingly hectic deadlines."

"The bottom line is, we depend on word-of-mouth recommendations from satisfied clients to keep the workflow constant; and to keep clients happy we invest in the best tools for the job, tools that allow us to bring our imagination and experience to bear on every project. People expect nothing less than our best, and providing it is at the heart of the team's job satisfaction."

Chris Martin, printMAX Head of Sales, explained how his company's expertise has served The Wrap Shop: "We have been long-term suppliers for The Wrap Shop, working with Steve from his first Roland VP300 back in 2008, to his latest acquisition, his Summa F Series cutter.

"The Wrap Shop is a product of its own success. As the scale of its graphics projects has grown and the demands on its machines increased, the company has invested in the best technology to meet that growth. As a specialist reseller printMAX has always been there to help ensure Steve gets the best return on his investment.The Wrap Shop is an interesting case, if not unique. It uses roll fed printers and most Summa F Series cutters go to sites using flatbeds. However, Steve had seen the cutter in action. He could visualise its potential as part of his existing workflow and see how it might improve his productivity - which has proved to be the case."

Chris added: "Because The Wrap Shop is a long-term customer, printMAX has developed an in-depth understanding of its needs. This helped us ease its step towards purchasing the Summa F Series. The machine clearly met and exceeded the requirements of the company, opening a new realm of cutting and routing to its workflow, while also bringing quality control in-house. Central to its success is The Wrap Shop team's creative skills. A lot of Summa F Series customers will only cut very basic and generic shapes, such as squares, but these guys really go to town on their designs. It's always exciting to discover what they plan to do next; they can inspire the most jaded imagination."

Managing Director Michael Bolton enthused: "With its core ethos of exceeding expectation, printMAX prides itself on transparency with its customers, and a part of this is our one-on-one business demonstrations in our Demo Centre. In its central South location, the Demo Centre has a huge range of machines, of which the Summa F1612 cutter has become a central feature.We offer customers an opportunity to book for live demos because we know that seeing and trying these machines first-hand provides an opportunity to experience this advanced technology and discover the incredible results they can achieve."

Steve Hart concluded: "I've known and worked with printMAX a long time; and when I told Chris Martin I was looking at investing in a Summa F Series - and he told me they were on the printMAX stock list - the whole thing became very straightforward.

"I trust printMAX to look after my technical requirements; they always have in the past and I will always use them in future. My customers know I will go that little bit further to meet their needs, I feel I get the same service from printMAX."

T'Go Creative

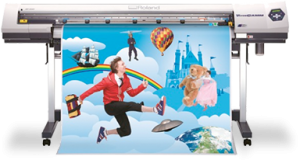

The Roland VG enables T'Go Creative to offer many of the products they had previously outsourced, along with offering new product opportunities, at a cheaper cost and higher quality.

The Roland allows us to take on many jobs we simply couldn't have said yes to previously, and of course allows us to control the quality. As designers, we are quite picky and although a client may not notice a slight colour difference, we do, so for us to be able to send out a perfect product, well that means it's been a worthwhile investment. We're putting the VG-640 to good use by launching in-house production of bespoke wallpaper. Being able to enter this growing and increasingly popular market is all thanks to the Roland, our partnered decorating firm cannot believe the quality and scratch resistance of the prints.

Following successful installation and training from printMAX, owner Gary Paterson has gotten to grips with the full potential of the Roland VG-640, his overall conclusion of his new purchase, "the new machine is a fantastic bit of kit. It produces excellent work and is simply one of the best investments I have ever made."

LR Designs

Lincolnshire based LR Designs have invested in the new Mimaki CJV150! They are looking forward to the promising future that their new purchase will bring them.

As a long established customer of printMAX, Lee Rudd at LR Designs was interested in specifically printing Orange for KTM motorbikes. Orange has always been a particularly difficult colour to match using the standard CMYK ink configuration so Rudd approached printMAX to look at what options are available.

Lee Rudd set up LR Designs in 1997 and since then they have fledged into market leader within their sector. Having been in the industry for 19 years, LR Designs have seen their client’s needs change and adapt as the technology of print has developed.

Focusing on design and production for custom race bike graphics but also offering a range of print outputs to the race industry and general public.

printMAX recommended the Mimaki CJV150 print & cut solution which has 10 ink colour options, including Silver, Orange, Light Black & White inks. The CJVI50 is an exceptional printer, offering a faster print of up to 56.2m² per hour, allowing them to increase the number of tasks, ultimately upping production while allowing LR Designs to hit the KTM orange.

Working directly with customers, as well as Bike dealerships and race teams LR Designs are excited to introduce the capability to print the direct colour code requirements of KTM Orange to their customers.

Lee from LR Designs says "we have found that the colours are much better on the CJV, we love how bright and vibrant they area."

Looking to the future LR Designs are excited about what is to come, “we are looking forward to broadening our horizons as we learn more about the possibilities that the printer can offer us, Mimaki gives us more control over our print, allowing extra options and variations.

printMAX sales manager, Chris Martin adds, "The Mimaki enables LR Designs to offer KTM orange as a new venture, which they had previously not been able to produce, along with offering new product opportunities at a higher quality, noting that the colours are extremely vibrant."

The team at LR Designs have now gotten to grips with the full capability of the Mimaki CJV150, Lee says "at first it was challenging for us to get used to the change between our existing printers and the Mimaki, however, moving forward with the new machine is really exciting. It produces excellent work and we can see the huge potential to our business. The KTM orange was a strong requirement in our purchase, printMAX have offered continual advice and support in how we can achieve this, I'll definitely be using them again."

See the CJV at work at The Print Show 2016 11th -13th of October, find us on stand D5O and the Printers Bizarre area. To find out more information visit http://printmax.co.uk/blog/printmax-returns-to-the-print-show-with-inspiring-mimaki-line-up/

We are currently running a trade in promotion, upgrade your old printing to a new CJV 1.6m and receive £2500 back. To find out more information visit http://www.printmax.co.uk/offers/

To learn more about Lee and LR Designs, visit http://www.lr-designs.co.uk/

For more information on the Mimaki's CJV series, visit

http://www.printmax.co.uk/hardware/mimaki/print-and-cut/

printMAX are also offering demonstrations on this and many other products from their Southern demo centre, call +44(0)1420 511539 to schedule an informal meeting and see the technology first-hand.

KT Litho

Established for over 33 years with the promises of quality, performance and delivery, Lancashire based printers, KT Litho are a well-established and reputable operation.

With a history in litho printing and processes, brothers Greg Twemlow and Matt Twemlow, Joint Managing Directors, have been leading the company with continuous growth and expansion.

"We have a large base of customers that rely on us for high quality output, something we really pride ourselves on at KT Litho. Having been in business for as long as we have, it's important to keep up a good reputation."

However, KT Litho faced a problem often seen in high volume print rooms, their orders were diversifying.

"The majority of the time we see high volume, repetitive orders, which reflects the processes we have had in place. In 2005 we started to see an increase in demand for bespoke, short run orders. Using the technology we already had in place, the short run items were proving too expensive to produce."

Seeing a growing trend in demand, Greg looked to the marketplace to see what might be on offer that could keep high-volume clients satisfied whilst reducing the costs of bespoke items.

As an initial solution, KT Litho invested in two Roland VersaArt RS-640s, this allowed for quicker printing but still required finishing times for drying and mounting, ultimately not resolving the core requirement.

Greg then looked to the seemingly evolving flatbed printing technology when printMAX introduced him to the Mimaki JFX200-2513.

Designed for ease of use, high quality but in a cost effective package, the JFX200 offers an affordable entrance to flatbed printing.

With highly productive print speeds of up to 25M2 per hour, the JFX enabled KT Litho to continue with their high volume orders. However, using the Rasterlink RIP software and with the ease of loading and precise positioning media thanks to the vacuum bed and pin system, KT Litho could print bespoke jobs for the same cost by reducing set up time and ultimately enhancing the print potential.

The instant drying of the ink, a feature possible through the energy efficient LED UV curing, allows for continuous printing with little to no additional finishing time.

The beauty of direct to substrate printing is in the potential. There are endless possibilities for diversification and print capabilities. Greg adds, "since taking on the JFX200 we have started taking enquiries for glass, metal, wood and several other items that we would never have considered before, and would have certainly turned away as a business opportunity."

KT Litho made the decision to go for the JFX200 following the assistance and knowledge of Mimaki reseller, printMAX.

"Having met printMAX's MD, Michael Bolton over 10 years ago, he left me with the lasting impression of honesty, enthusiasm and integrity. Three features I see as key in any business relationship. Having dealt with several suppliers over the last 30 years of trading, none have come close to treating me the way printMAX have."

Ainsley Signs

Manchester based Ainsley Signs have provided a dedicated sign service for over 50 years. The family run company boasts a variety of clients covering broad industry sectors. With a base of consistent and loyal customers, along with new business and contracts, Ainsley Signs faced the production bottleneck that is seen so often in the print business.

In order to maintain their existing workload and confidently secure new business, Ainsley Signs would need to invest in a new large format printer. Having made the decision to take their business to the next level, they looked to their past.

Josh Ainsley, Commercial Director explains, "We have a number of Roland machines and are happy with the overall product. We first bought a Roland printer back in 2000 and are still using it today. Our past experience gave me the confidence to stick with Roland, as the old saying goes, "if it isn't broke, don't fix it! So a new Roland was a no-brainer."

Having kept a keen eye on the new releases from Roland, Ainsley Signs opted for the newly launched SolJet EJ-640.

Roland's EJ-640 offers rugged construction and low operating costs, allowing for higher volume printing with the introduction of the new EJ inks, available in 1 Litre cartridges. With economical design features, the EJ-640 is positioned as a long-running, low-maintenance production machine, designed to improve productivity and quality whilst lowering running costs.

The Roland SolJet EJ-640 uses dual eight-channel Piezo heads, staggered to cover a large print width, and arranged in a mirrored formation to reduce the chance of chromatic banding.

Alongside the new ink, you'll find new VersaWorks Dual RIP Software, incorporating native PDF processing and a new media feed system, encouraging more accurate and precise take-up.

The reasoning behind Ainsley Signs' purchase decision is fairly obvious, "the business we work in, and the clients we work with are all about the turn-around time, the EJ was a fantastic choice due to its speed and quality.â"

Purchased from Roland dealer, printMAX, Ainsley Signs were the first in the country to receive the brand new SolJet.

"About 2 years ago I started looking into the solutions available, having posted a question on twitter, printMAX responded instantly with advice, information and confidence in their products. The install was great, showing us everything we needed to know. printMAX have always gone the extra mile for us and I've built a great relationship with them as a result. Relationships with our suppliers has always been a big part of our purchasing decision, you need someone reliable and time conscious so that you can offer the same to your clients."

Whilst Ainsley Signs aren't producing anything new, they have increased their workload and can now confidently take on new clients without the worry of missing deadlines or compromising on quality. The EJ-640 is currently working flat out with their existing Roland VersaCAMM VS-640i to produce signage for a long-standing client in the home building industry.

Mr Nutcase

Mr Nutcase, an online personalised phone case company purchased the Roland VersaUV LEF-12 flatbed printer, this has enabled Edward and his team to print directly onto phone cases using a customised jig which allows for individual personalisation at greater speeds.

The Roland VersaUV LEF-12 is the younger brother to the new LEF-20 which Mr Nutcase have since upgraded to in order to meet demand.

Edward Ockleford, managing director of Mr Nutcase said, "The Roland VersaUV LEF was the perfect choice for our personalised phone case business. It is an extremely versatile printer that offers high quality white and clear print options, plus a host of special effects to create striking textured effects on a range of phone cases and promotional goods. As an online business allowing customers to upload their own images, the ease of versaworks and flexibility of the software is a huge benefit to us. The Roland LEF will enable us to continue to produce the products our customers love at a speed and quality that works for our business. A big thanks to the team at printMAX for their ongoing support.

You can learn more about Mr Nutcase and their personalised phone case printing at http://www.mrnutcase.com/

DGS Supplies

Dudley-based DGS Supplies invested in a Mimaki JFX200-2513 LED UV flatbed printer to print direct-to-board and reduce time consuming finishing techniques.

Managing director Franc Moscato describes the company as "We're specialists in construction, PPE, signage and promotional goods and printing".

The Mimaki JFX200 Flatbed allows the company to reduce production costs with direct to substrate printing and fast speeds.

"After 10 years in the printing industry, the JFX200 is by far the best printer I've worked with. It's simple to use and great quality and we received excellent training from printMAX. The whole process from ordering the JFX200 through to the four day installation and training has been faultless, along with the follow up support." - Matt Shaw, print manager.

The JFX200 delivers super fast speeds and stunning print quality direct to rigid substrates. Its 8' x 4' bed size not only provides a seamless platform for conventional board printing; the JFX200 offers so much more by way of potential applications for companies looking for new revenue streams and a more creative string to their portfolio bow.

Personalised Memento

Personalised Memento first spoke to printMAX about their large format printer needs when they were printing clock faces using self adhesive vinyl. The vinyl can be printed on most of the Roland range, however the VS-640 gave the reliability and versatility that would allow personalised memento to produce a variety of printed promotional items.

Personalised Memento decided to go with the Roland VS-640, the larger of the VersaCAMM range as a great solution to their printed vinyl needs.

Signpost Signs

Signpost Signs first started looking at producing large format print in-house back in 2008. At that time they were looking for a 64" print width print and cut machine, unfortunately there was not an all-in-one solution available that satisfied their requirements so the company opted for a separate print and cut set-up with a Roland SolJet Pro 3 XJ-640.

Following the release of the Roland SolJet Pro 4 XR-640 release back in September 2012, Signpost Signs had no hesitations in upgrading their existing Roland set-up.

"The integrated print and cut facility on the Roland SolJet Pro 4 XR-640 is just what we were looking for. Artwork and production times have been greatly reduced. Within just two weeks of having our XR-640 we were running our largest print and cut job to date! (Over 150M of print). However, the XR-640 does not only offer speed, the feature we're most impressed with is the white ink improvement - we look forward to marketing this and offering more versatility in the future."

"From initial enquiries 5 years ago, as digital print 'virgins', printMAX have advised on new printers, upgrades and consumables without the pushy sales approach you might expect from such a competitive market. PrintMAX have proven to be a wise choice as our chosen supplier for all Roland products."

Vision Signs

Vision Signs first spoke to printMAX at Sign & Digital UK 2012 exhibition in Birmingham. We were exhibiting there with a variety of Roland printers on the stand and some great offers on these.

The need was general usage, nothing specific but a reliable, good large format printer at a good price. He had brought a friend along with him who was an existing Roland user who had relied upon the SP in his own business. The existing user friend was a great advocate of the Roland technology and really supported the SP-540i for its general use printing.

The versatility of the Roland SP-540i meant that Vision Signs were able to produce a number of products from signage to banners, posters and the general items you'd expect a good printer to be able to produce.

Frantic Graphics

Frantic Graphics were looking for a large format printer that would enable the production of vinyl graphics for vehicles, shop fronts, signs and windows.

After some advice and support from printMAX, the decision was to go with the SP-300v; a great general usage large format printer.

After our technical consultant, Simon Coff, installed the printer Frantic Graphics were highly commendable of both the printer and the service they received with printMAX.

"The SP-300v is working great. I'm very happy with it and the great service you guys provide. Simon's training on the Roland SP-300v was excellent. Sales Manager Chris Martin and Financial Controller Charlotte Whele were a great help too!"

Golden Leaf Designs

Paul at Golden Leaf Designs was looking to print on mainly textile garments for a variety of sports clubs and teams. Before installing his large format printer from us he was using a cutter to cut coloured signmaking vinyl. However, the process of layering the various colour vinyls was taking too long for the volume of work he was producing.

After speaking to printMAX we managed to find him a great 2nd user VP-300i. This was well within his budget and allows him to print the design so that he can apply directly to the garments rather than constructing the colours separately.

The Roland VP-300i has saved Paul a large amount of time and energy, allowing him to take on more work. Not only will he now be able to produce the graphics for the sports garments but he will be able to produce a variety of decals and items using his large format printer.

Weedoo Signs

Berkshire based Weedoo Signs took the next step in their business growth back in October 2014 with the investment of a Mimaki JFX200 flatbed printer.

The company was struggling to meet the growing demands of their customer base, never a tough problem to face but in terms of resource management, time allocation and overall print capability Weedoo were certainly at a crossroads. The decision to look at the Mimaki JFX as a solution came when printMAX took on the Mimaki product range.

"We had been looking for a product that would take us up to the next level for quite a while but as is always the way, time gets away and the decisions get put off. When printMAX took on the Mimaki range they introduced us to the JFX and after a one-on-one demo we were able to see the opportunity immediately."

Following the installation and training from printMAX, Weedoo have been able to confidently print direct to board along with offering a more diverse portfolio of services.

"We've been able to take on more work than ever, work that we might have had to turn away due to the print requirements and resources available. The JFX certainly adds diversity to our work along with completing our existing projects in a much more effective manner."

The Mimaki JFX200 has been causing quite a stir within the industry this year. Having won multiple awards and impressing in terms of both speed and quality, printing up to 25m2/hr with a maximum print space of 2.5 x 3.1M.

printMAX MD, Michael Bolton comments, "The JFX allows benefits in terms of removing processes, with regards to Weedoo Signs this was clearly going to help with their time and production restraints. Where Weedoo Signs would have previously had to print onto roll to roll media and then mount to board they now need only print straight onto the board using the flatbed printer, this has ultimately saved time and money with regards to purchasing media and man power."

With a print depth of 50mm the application possibilities on the Mimaki JFX are vast. Weedoo signs specialise within the signage industry so have benefitted from being able to print direct to board and hoardings. Machine operator Stuart Barker adds, "The intended use for the JFX was to print directly onto large scale signage and wayfinding, however, we've seen a particular benefit within our interior graphics services. The flatbed can print onto pretty anything, within reason, and the result on glass and Perspex is visually, very appealing. We didn't foresee this as an area of growth for the business but has added real value to our product offering."

Production Manager Jeff Bufton adds, "The JFX200 really has allowed us to work at a much faster production rate than ever before, I've been able to streamline the business and enable the team to work far more efficiently. For such a large bit of kit it is also surprisingly easy to use, after the 4 day installation and training process we were fully prepared to use it at maximum capacity."

Isle of Wight NHS

The Isle of Wight NHS first called us with the need to be able to produce outdoor signage. Whilst they have a Canon for the indoor requirements they have had a Roland large format printer before and knew it could really perform with outdoor prints.

After some consideration they went for the Roland VS-640. Most of the Roland range would have worked for them as the Eco Sol Max inks allow outdoor signage with the 3 year outdoor durability they offer.

The VS-640 was perfect, not only does it print the outdoor signage that it was initially required for but also banners and vehicle wraps.

After the install from printMAX Isle of Wight NHS were fully educated in how to use the Roland printer.

"It was a really good install. We learnt a lot in the two days that Simon was here. A great explanation of the VS-640 itself but also the best materials to get the best finish out of it."

ORC Printwear

ORC printwear spoke to us about their large format print and cut requirement. They needed to primarily produce sports clothing.

Looking at the Roland large format printer range there were several options they could go for. In the end they decided to go with a cutter and a printer.

The GX-24 vinyl cutter is used for fewer colour designs where only one or two colours are used, for instance names and numbers on sports shirts, where as the addition of the Roland SP-300i allows them to be able to produce high detailed logos and badges.

Not only does this solution fulfil the inital requirement but it also opens the doors to a lot more business opportunity, with the SP-300i and the GX-24 ORC printwear can offer additional advertising services to the existing sports club customers, from banners and posters to promotional items.

Regarding the install from printMAX, ORC printwear were extremely complementary, adding "printMAX were really helpful. They provided thorough training on the SP-300i which didn't feel rushed at all!"

Smith Signs

Smith Signs Ltd Guernsey took delivery of the hybrid flatbed printer, which will enable the team to explore a host of new applications, from packaging prototypes to wide-format signage, exhibits and window displays.

The Roland VersaUV LEJ-640 is a 64" that prints CMYK, white and clear inks on virtually any substrate up to 13mm thick. A variety of media can be used to create eye-catching work, including three-dimensional custom patterns and embossing effects all of which produce dramatic results.

Dan Smith, managing director of Smith Signs Ltd Guernsey said, "The Roland VersaUV LEJ-640 is an excellent addition to our range of print hardware. It was an obvious choice as the LEJ-640 is an extremely versatile printer that offers high quality white and clear print options, plus a host of special effects to create striking textured effects on a range of media. It will enable us to expand our range of services. A big thanks to the team at printMAX for their support, both pre, post and during the installation process."