Mimaki’s UV flatbed printer, the JFX, is one of the industry’s most popular entry-level flatbed solutions.

The bridge between introductory hardware and industrial capacity; the JFX provides an entry level solution to flatbed printing, with high productivity, good value and a stable and reliable chassis.

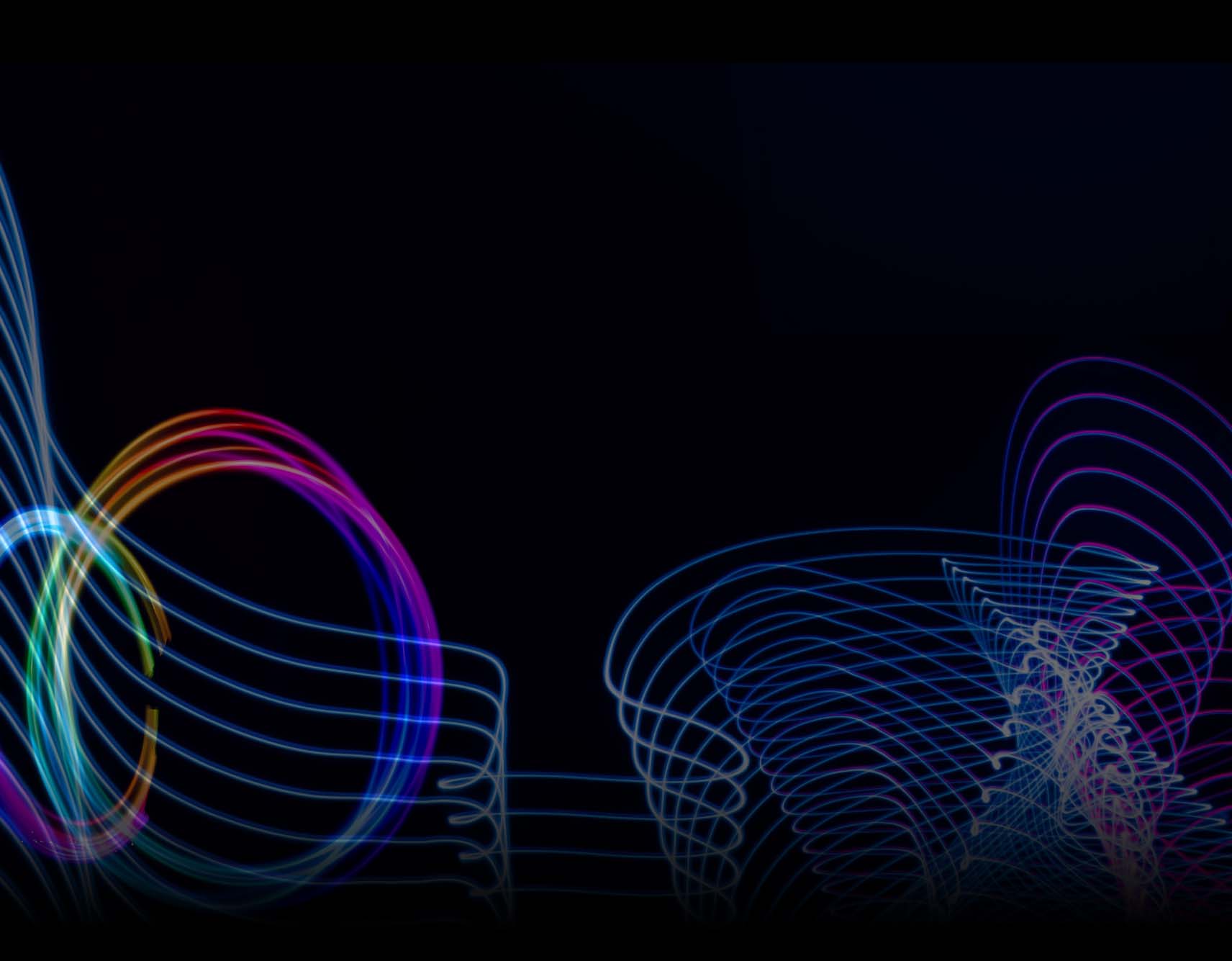

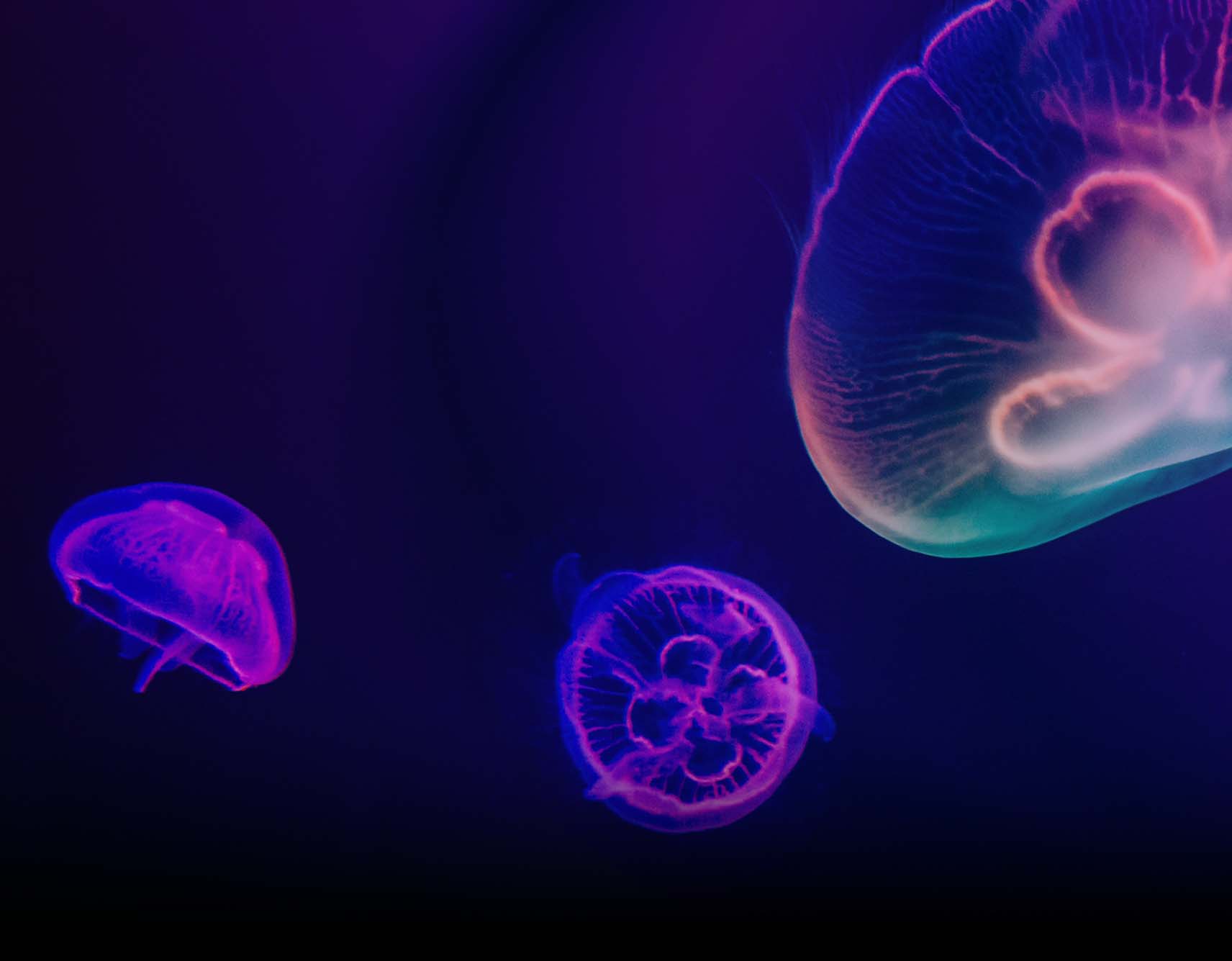

With the ability to create texture, vibrant graphics and long-lasting print, the Mimaki JFX flatbed provides true versatility.

As an entry-level hardware option, we know that there are likely to be plenty of questions you might have when considering an introduction to the LED UV flatbed printer market, so our Head of Sales, Chris Martin, has put together the questions he’s most frequently asked, and his answers, to help guide your search for your next printer.

Q: What application uses does the JFX and LED UV flatbed technology offer?

A: The opportunities are vast. From signage to furniture, POS displays, advertisements, wall displays and more. With the ability to print onto rigid media and composites, plus irregular shapes, the list of applications is longer than this blog would allow.

Q: I have a specific need and media requirement, will the JFX work?

A: If you’re relying on one specific output, perhaps a niche material to print on, the best suggestion would be to arrange for some bespoke samples. Along with offering in-person demonstrations at our Hampshire based Demo Centre or in Crewe, Cheshire, we can also provide samples on your material, meaning you can be completely confident in the printer’s suitability before you make your purchase decision.

Q: How fast is the Mimaki JFX?

A: There are different sizes available, and each will deliver variable speeds, which will also differ depending on your output requirements; level of detail, texture requirements and print density.

The JFX500 flatbed printer is the production option when it comes to the Mimaki JFX range, with production speeds of up to 60 sqm/h at a high level of detail; down to 2 point text on a 210cm x 310cm print area.

Q. Will I need training on the Mimaki JFX Flatbed?

A. If you’re new to the machine, yes. Our support team offer installation and training over a full four day period, making sure that when our technician leaves, you’re up to speed on everything that the JFX offers, with specific focus on the jobs you plan on running; from the RIP software to changing the inks and everything in between. Our technical consultants come from a printing background, so are able to provide superior application advice with focus on realistic day-to-day printing.

We then also provide ongoing support when you need it. The UV flatbed has great potential, including the ability to print texture; for braille, decorative finishes and more. This may not be something you want to achieve on day one, but should your requirements change, we’ll be able to guide you through this, when the occasion calls for it.

Q. What happens if something goes wrong?

A. If you’ve purchased your Mimaki JFX flatbed printer from printMAX, we’ll endeavor to resolve your issue remotely, with our own support team. However, each model also comes with at least one year’s warranty, plus the option of extending this further down the line. Our support team will get in touch ahead of the warranty expiring to give you the opportunity to extend, avoiding any lapses.

Q. What type of inks does the JFX use?

A. The JFX200 uses LUS 120/150/200/350 or LH-100 in 1l bottles and the JFX500 uses a 2l ink station with either the LUS-120/150/200 or LH-100 range. All of which are readily available from our sales team.

The LUS-150 and LUS-120 tend to be the most popular choices, they’re both relatively versatile inks so offer users optimal choice for application. LUS-120 tend to be used more if people want to print and then cut as they are a bit more flexible so tend not to crack, but LUS-150 has greater adhesion properties, so more suitable for harder surfaces, for instance printing direct to acrylic or di-bond.

Q. What is the printed life expectancy of the Mimaki JFX ink?

A. There are two types of ink available; hard or flexible. Your output requirements will determine which ink we recommend. The hard ink has very little weather resistance, so would not have as long of an outdoor lifespan, water seeping beneath the ink and media layers will cause the ink to lose adhesion.

The flexible ink, on the other hand, has higher weather resistance.

Q. What is the lifespan of the UV lamp?

A. This will all depend on your usage of the printer; frequency and strength settings, but generalized, the lamp should last for 5,000 hours or more.

Q. What is an ionizer and do I need one?

A. An ionizer is an anti-static device, it helps to reduce the static electricity on your print surface. It is attached on the side of a printhead carriage.

Q. Why do I need to remove the static?

A. The problem with static electricity on the surface of your media is that is can cause significant print quality and printer problems. Certain types of media will create varying levels of naturally occurring static, but the printer environment also comes into effect; for instance if the printer rests on a carpeted floor, the static generated would be greater. The daily problem that you’ll face without an ionizer is ink misting; resulting in a fuzzy print, issues with calibration and clogged nozzles.

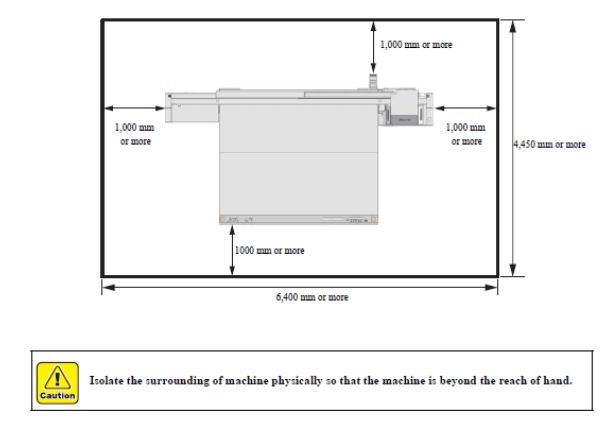

Q. What space do I need?

A. The JFX200, the smaller device compared to the JFX500 requires the space below, which would obviously need to be scaled up for a JFX500. We carry out detailed site surveys before any install to remove any concerns and ensure that on the day, the install goes as smoothly as possible.

Q. What do I do next?

A. If this has given you a good idea that you’d like to proceed with the Mimaki JFX as an option, we’d like to welcome you along to a demonstration at our Demo Centre in Selborne, Hampshire, or alternatively in Crewe, Cheshire, whichever is nearest for you.

However, we know that’s not always achievable, so an alternative step would be to arrange for an example product to be shipped to us, along with demo artwork, as we would be happy to test the printer to your specific print, and artwork, requirements.

Either way, feel free to give me a call as I’ll be able to advise you on how to proceed, along with guidance on shipping, finance and more. 0800 567 7676/ 01420 511539.