Berkshire based Weedoo Signs took the next step in their business growth back in October 2014 with the investment of a Mimaki JFX200 flatbed printer from reseller printMAX.

The company was struggling to meet the growing demands of their customer base, never a tough problem to face but in terms of resource management, time allocation and overall print capability Weedoo were certainly at a crossroads. The decision to look at the Mimaki JFX as a solution came when their supplier of choice, printMAX, took on the Mimaki product range.

“We had been looking for a product that would take us up to the next level for quite a while but as is always the way, time gets away and the decisions get put off. When printMAX took on the Mimaki range they introduced us to the JFX and after a one-on-one demo we were able to see the opportunity immediately.”

Following the installation and training from printMAX, Weedoo have been able to confidently print direct to board along with offering a more diverse portfolio of services.

“We’ve been able to take on more work than ever, work that we might have had to turn away due to the print requirements and resources available. The JFX certainly adds diversity to our work along with completing our existing projects in a much more effective manner.”

The Mimaki JFX200 has been causing quite a stir within the industry this year. Having won multiple awards and impressing in terms of both speed and quality, printing up to 25m2/hr with a maximum print space of 2.5 x 3.1M.

printMAX MD, Michael Bolton comments, “The JFX allows benefits in terms of removing processes, with regards to Weedoo Signs this was clearly going to help with their time and production restraints. Where Weedoo Signs would have previously had to print onto roll to roll media and then mount to board they now need only print straight onto the board using the flatbed printer, this has ultimately saved time and money with regards to purchasing media and man power.”

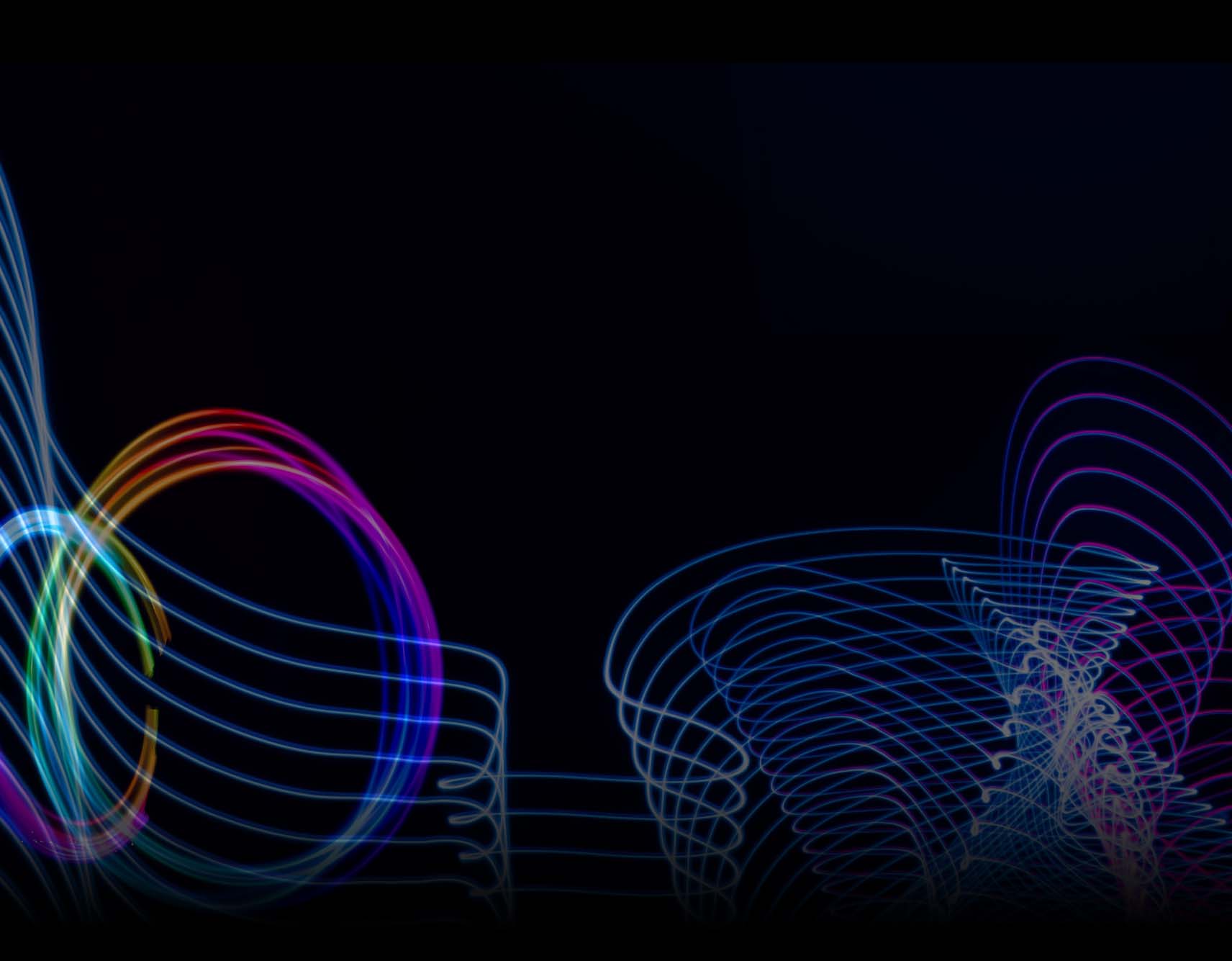

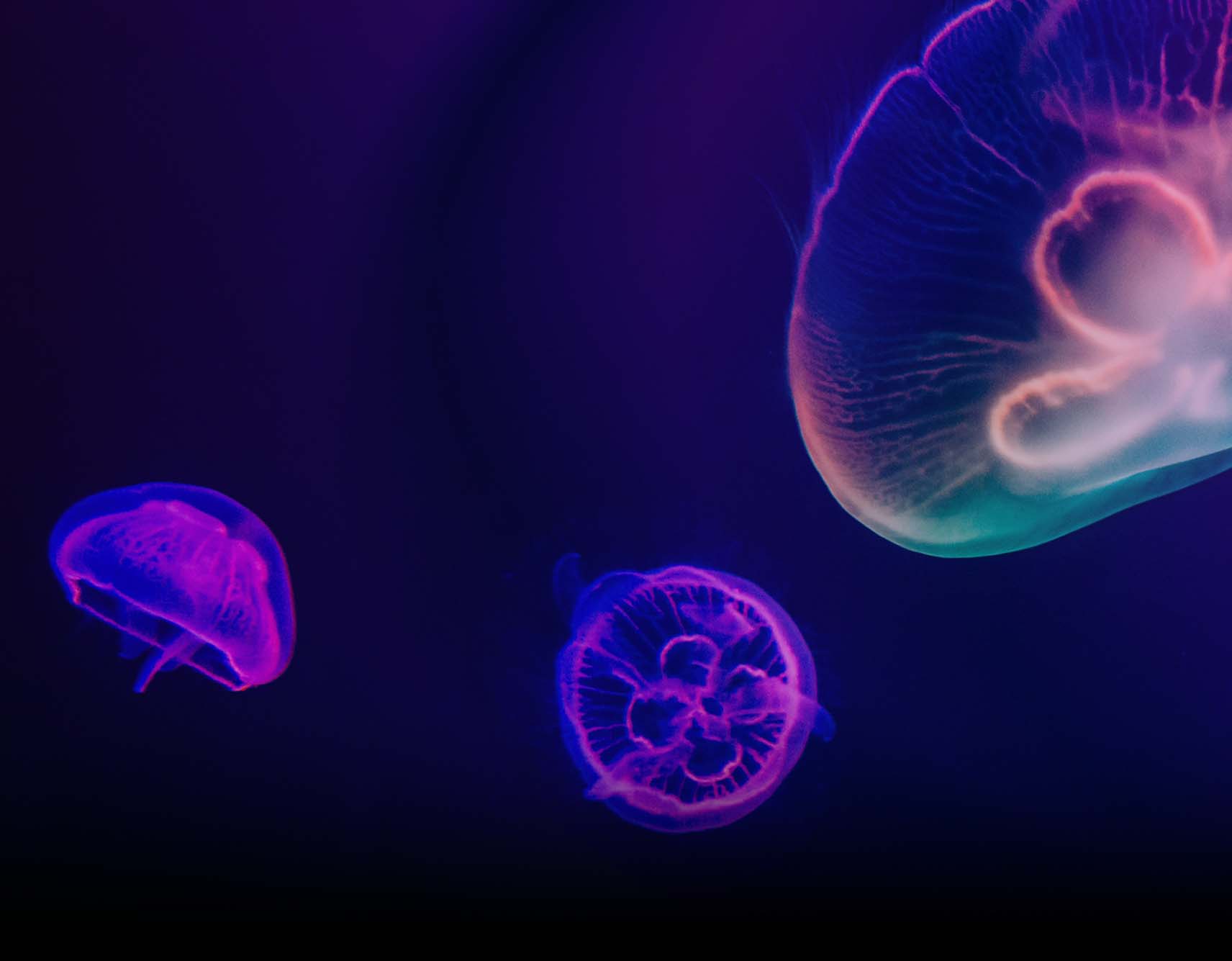

With a print depth of 50mm the application possibilities on the Mimaki JFX are vast. Weedoo signs specialise within the signage industry so have benefitted from being able to print direct to board and hoardings. Machine operator Stuart Barker adds, “The intended use for the JFX was to print directly onto large scale signage and way finding, however, we’ve seen a particular benefit within our interior graphics services. The flatbed can print onto pretty anything, within reason, and the result on glass and Perspex is visually, very appealing. We didn’t foresee this as an area of growth for the business but has added real value to our product offering.”

Production Manager Jeff Bufton adds, “The JFX200 really has allowed us to work at a much faster production rate than ever before, I’ve been able to streamline the business and enable the team to work far more efficiently. For such a large bit of kit it is also surprisingly easy to use, after the 4 day installation and training process we were fully prepared to use it at maximum capacity.”

For more information on the Mimaki flatbed range please contact printMAX on +44(0)142 511539 or alternatively visit http://www.printmax.co.uk/view-hardware/mimaki-jfx200

You will find the Mimaki JFX200 on printMAX’s stand at Sign and Digital UK this year, 24th – 26th March 2015, stand F30.